Chiller Replacement for Industrial Buildings: Planning and Budgeting Considerations

09 April 2024

Invest in chiller replacement by Protector Air Care in industrial buildings to optimise cooling operations. Explore planning and budgeting considerations.

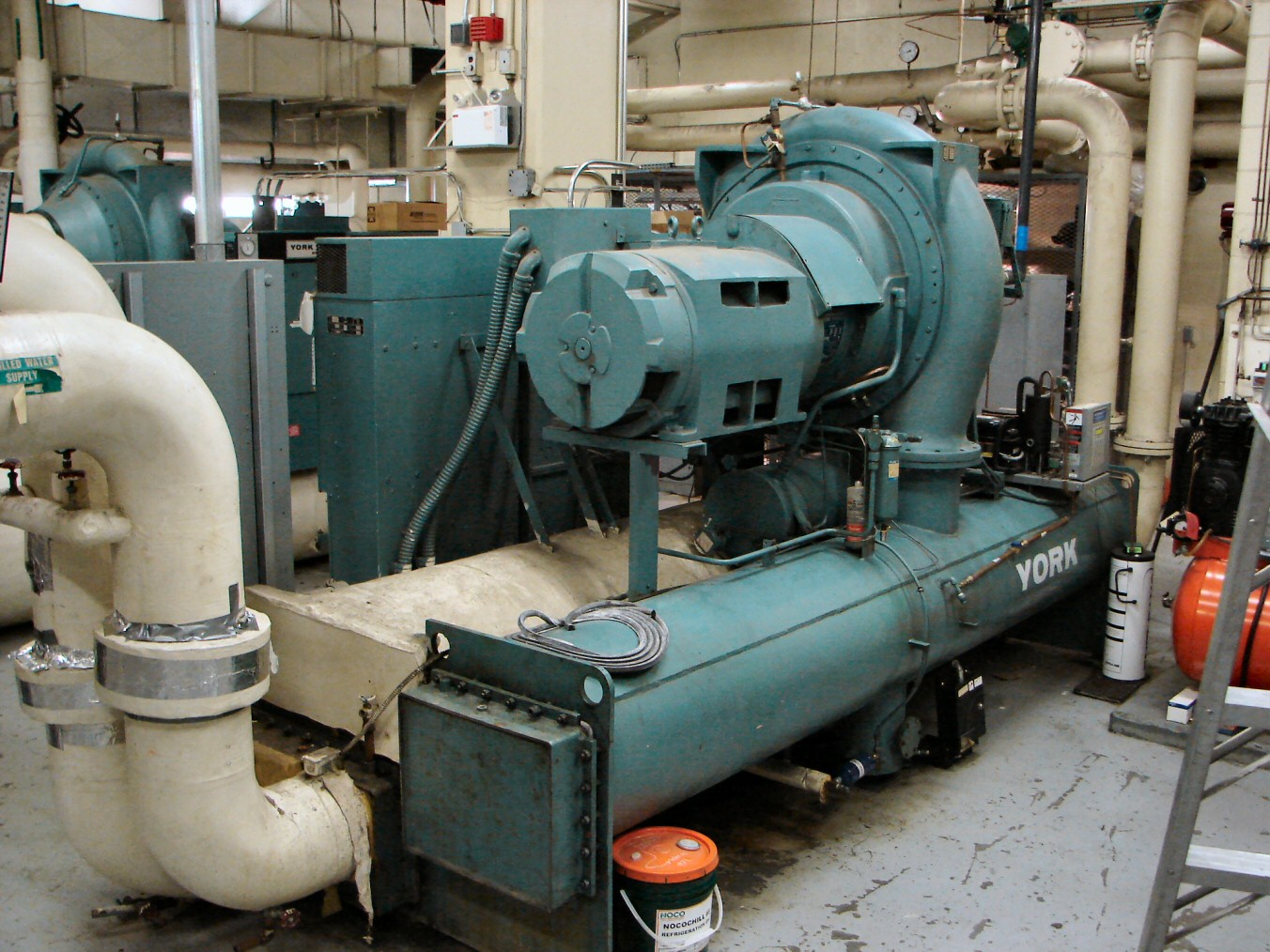

The optimal temperature for various processes and operations within industrial buildings can be guaranteed with chiller replacement. Chillers truly serve as the backbone of industrial cooling systems, but chiller replacement services may be required to optimise temperature control for various processes and operations within industrial buildings. These cooling solutions, like any mechanical equipment, have a finite lifespan. Hence, they may eventually require replacement.

Assess the Current Cooling System

Before embarking on a chiller replacement project, you must first assess the condition and performance of the existing chiller system.

One of the factors you must consider when conducting a comprehensive evaluation is the cooling load requirements. You must evaluate the current and future cooling load requirements of the industrial facility to determine the capacity and specifications needed for the new chiller system. You must also consider the age and condition of the chiller, including efficiency, reliability, and maintenance history. Ultimately, you must consider the energy efficiency rating of the existing chiller and explore opportunities for energy savings with newer, more efficient models.

Plan a Chiller Replacement Budget

Budgeting for chiller replacement involves estimating the costs associated with purchasing and installing a new chiller system. The following factors must be considered when setting a budget.

• Cost of new chiller unit: You must first research the cost of purchasing a new chiller unit that meets the cooling requirements of your industrial facility. Consider factors such as capacity, efficiency rating, and manufacturer warranties.

• Installation costs: You should also factor in the costs associated with chiller installation, including labour, equipment hire, and any necessary modifications to existing infrastructure.

• Ancillary equipment and accessories: Additional components such as pumps, piping, valves, and control systems that may be required to integrate the new chiller into the existing cooling system must also be considered during the budgeting phase.

• Maintenance and operational costs: Other things you must consider when setting a budget are the long-term maintenance and operational costs associated with the new chiller system, including routine servicing, repairs, and energy consumption.

Executing the Chiller Replacement

A plan is necessary to execute the chiller replacement project effectively. A detailed project plan should outline the timeline, coordination with stakeholders, and safety protocols. Your timeline must consider factors like the equipment lead times, installation requirements, and potential downtime for the industrial facility. All relevant stakeholders must also be coordinated optimally to ensure alignment and smooth execution of the project. Outlining comprehensive safety protocols is likewise needed to mitigate risks related to chiller replacement activities.

Pick the Right Chiller Replacement

Selecting the right chiller replacement solution is critical for meeting the cooling needs of industrial buildings while maximising energy efficiency and operational reliability.

To minimise operating costs and reduce environmental impact, choose a chiller with a high energy efficiency rating. Your chiller system must also be capable of accommodating the current and future cooling load requirements of your facility, with provisions for scalability and expansion. You must likewise opt for one with advanced features like variable speed drives, intelligent controls, and remote monitoring capabilities for enhanced efficiency and control.

Chiller replacement, which can be done by Protector Air Care, requires careful planning and budgeting to ensure successful outcomes and optimal cooling solutions. By conducting the previously stated steps, you can minimise downtime, maximise energy efficiency, and achieve long-term cost savings.

Optimized by NetwizardSEO.com.au

10 °C

10 °C